OUR EXPERTISE

INJECTION MOULDING

For over 15 years, we have worked with the software CYCLADES, which allows us to monitor and optimise all moulding and finishing processes in real time.

OUR EXPERTISE IN

THERMOPLASTIC INJECTION

OUR PLASTIC INJECTION MACHINES

Delta Plasturgy has 22 plastic injection machines ranging from 25T to 400T including the ARBURG and ENGEL brands, controlled by microprocessors and located on the line.

We also have:

- 4 pneumatic KAP presses;

- 1 SMOP press;

- 1 microprocessor-controlled SUPERMATIC press.

All of our presses help transform any type of thermoplastic including elastomer thermoplastics.

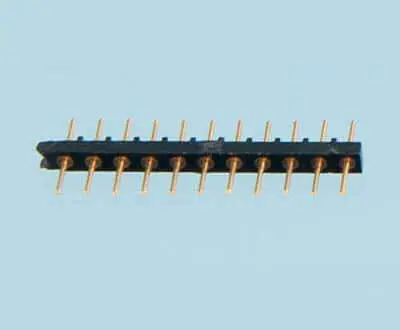

We have historically maintained and developed our micro-injection experience using a KAP press, a specific mini-mould technology and SMOP mould, which is now used to create very small fragile parts through overmoulding, such as connector parts

MOLD STORAGE

Delta Plasturgy has over 1,000 active moulds ranging from one impression moulds to 16 impression moulds, multi-version moulds or with multiple drawers for complex shapes. Moulds are stored, insured and maintained. We are one of the few plasturgy companies to have a fire protection facility to protect our clients’ moulds.

PLASTIC INJECTION MOULDING:

OUR ACHIEVEMENTS

Delta Plasturgy creates the following main injected parts:

- Connection supports, alternator terminal blocks, temperature-resistant polyetherimide power contactor elements, connectors

- Polycarbonate or polymethacrylate control buttons

- Transparent parts, measuring device windows

- Various technical parts in Vespel or Torlon

- Telecommunication station facades in PBT or in polyamide filled with glass or carbon

- Victrex Peek Coils, Mirrors, Accessories

- Boxes in PPS Ryton, supports, facades of telecommunication stations in PBT or in polyamide filled with glass or carbon

- Seals, stops, buttons or elastomeric parts for medical devices

- Thin-walled helmet shells in PE, PA or impact ABS

FLEXIBLE PIPE TO REPLACE RUBBER

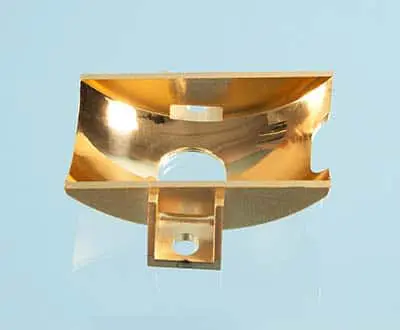

FINE GOLD MIRROR METALLISING

THERMOPLASTIC INJECTION OF PRECISION PARTS