A know-how in plastics

rarely equaled.

Fabrication Additive

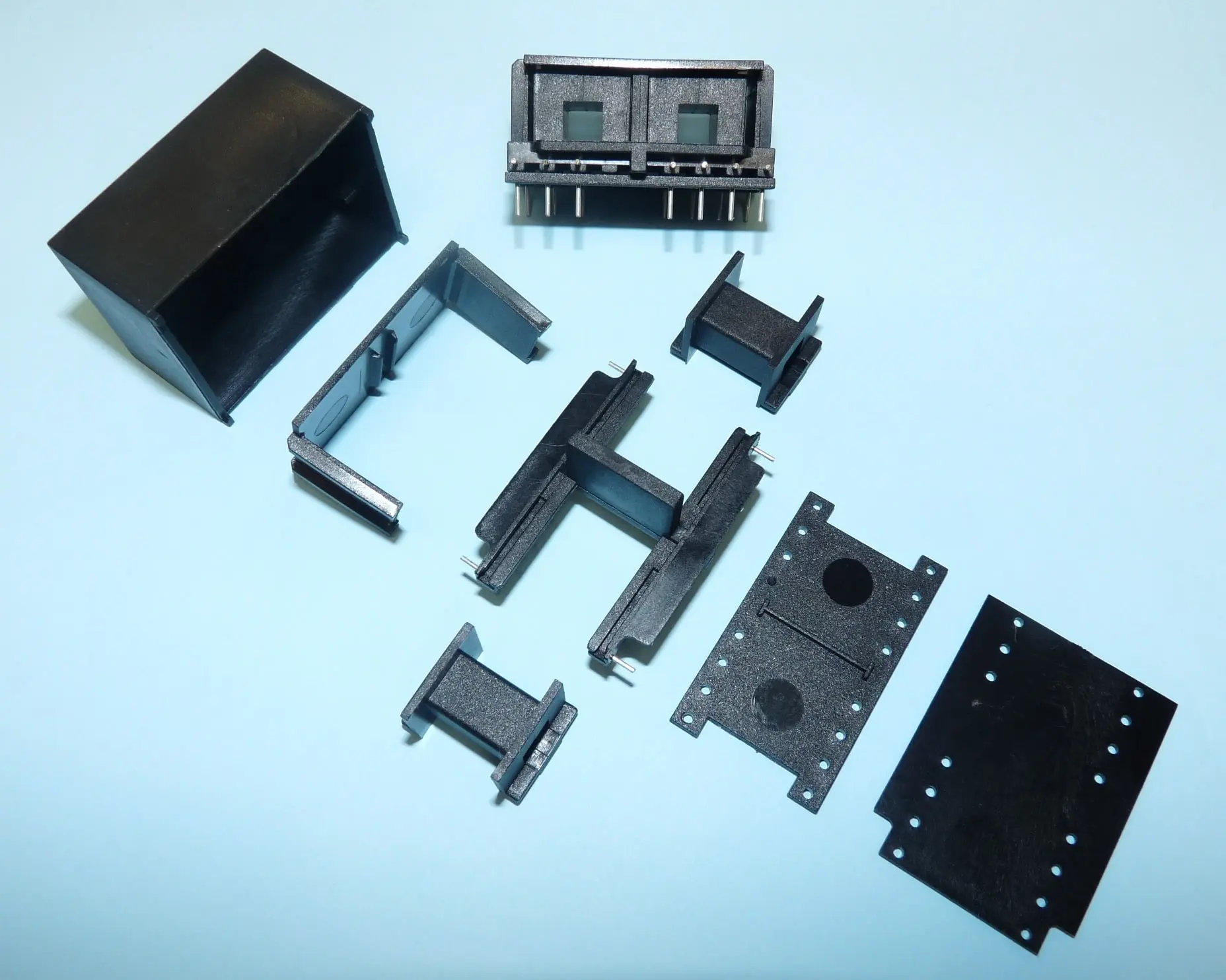

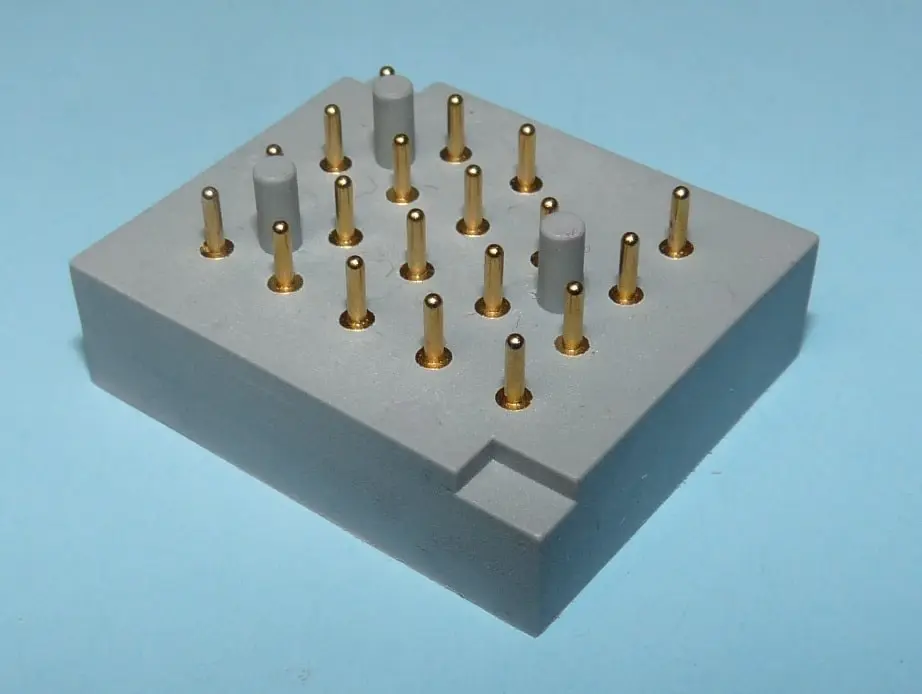

Insert overmoulding

Compression moulding

Injection moulding

Injection moulding, compression moulding and insert overmoulding.

The Delta Plasturgy group has transformed a wide range of highly technical plastic materials through thermoplastic injection and thermosetting compression molding processes, and is noted for its specialism in insert overmolding of all kinds.

We are proud of 60 years history and know-how in high performance plastics transformation:

- Over 150 plastic raw materials processed

- Transformation of all types of raw materials including PEEK and Polyimid

- Large variety of molding processes

- Over 2000 different manufactured part references

This know-how allows us to realize the most complex parts in small and medium series.

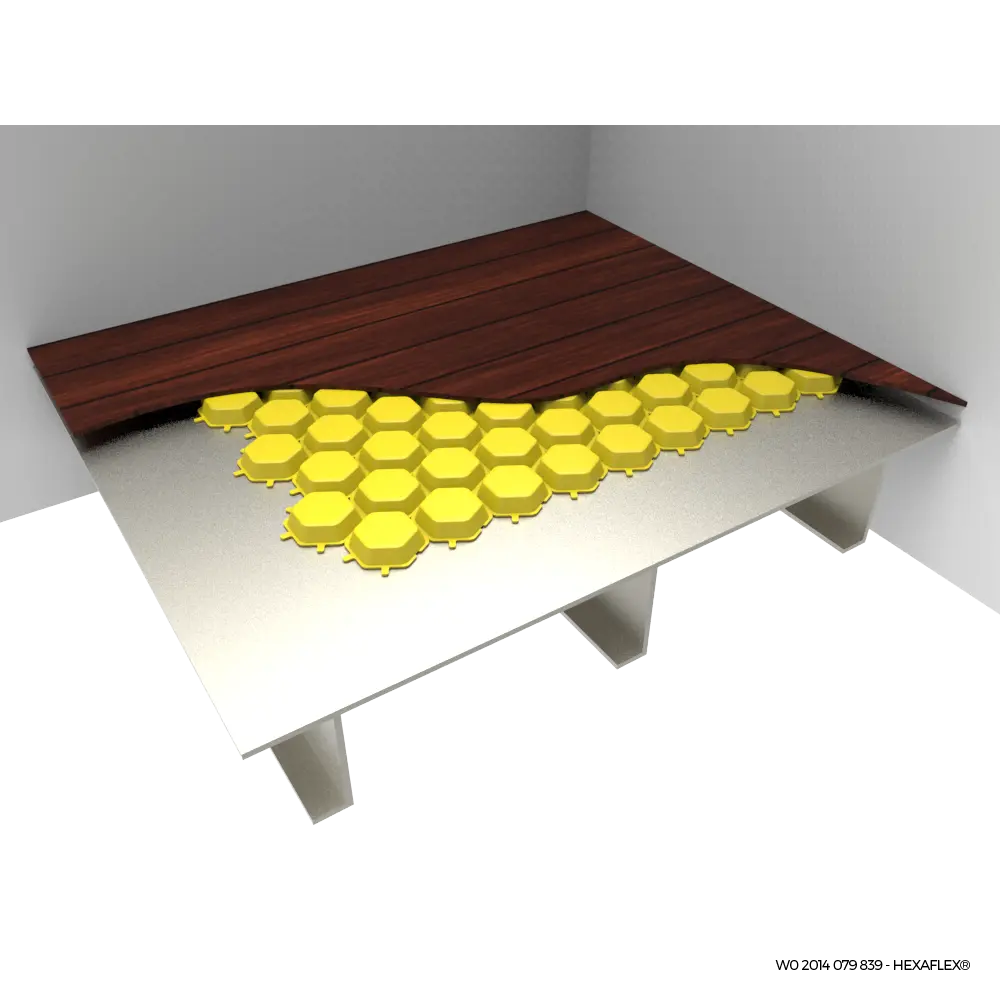

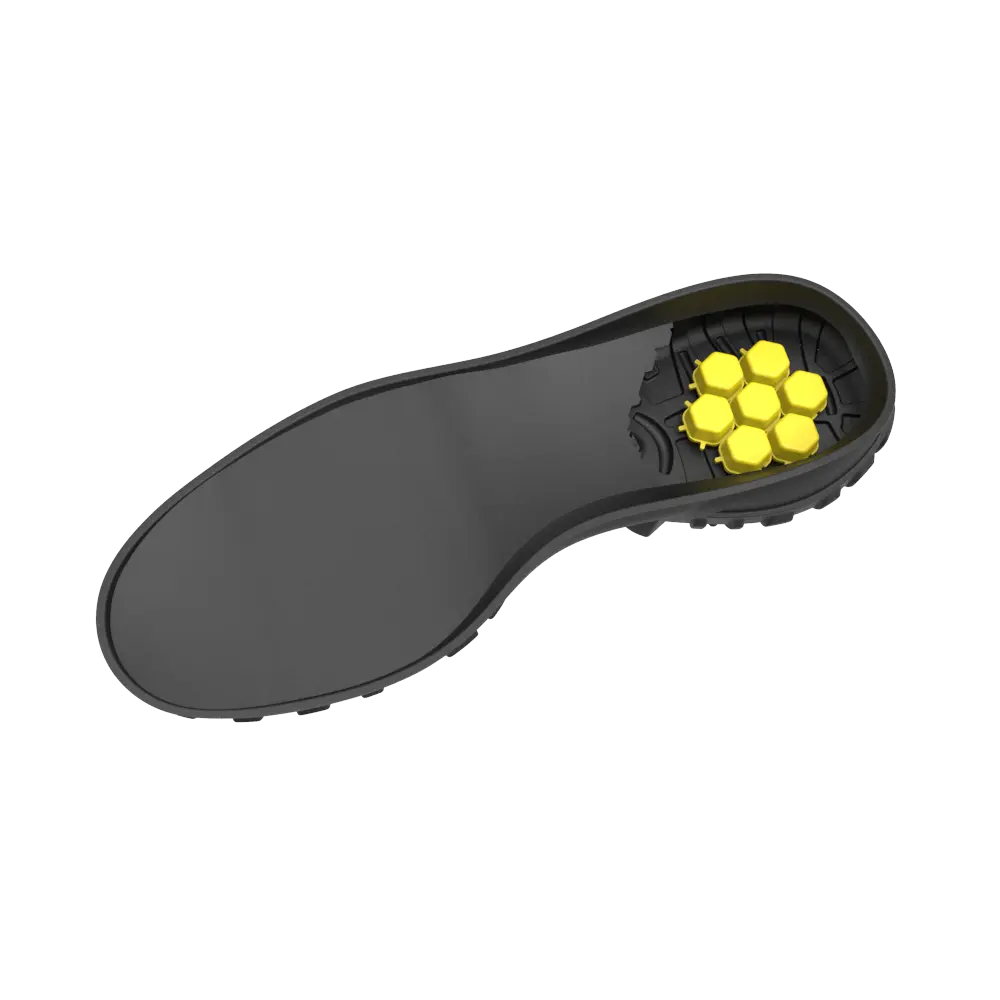

Discover Hexaflex

Our innovative own solution

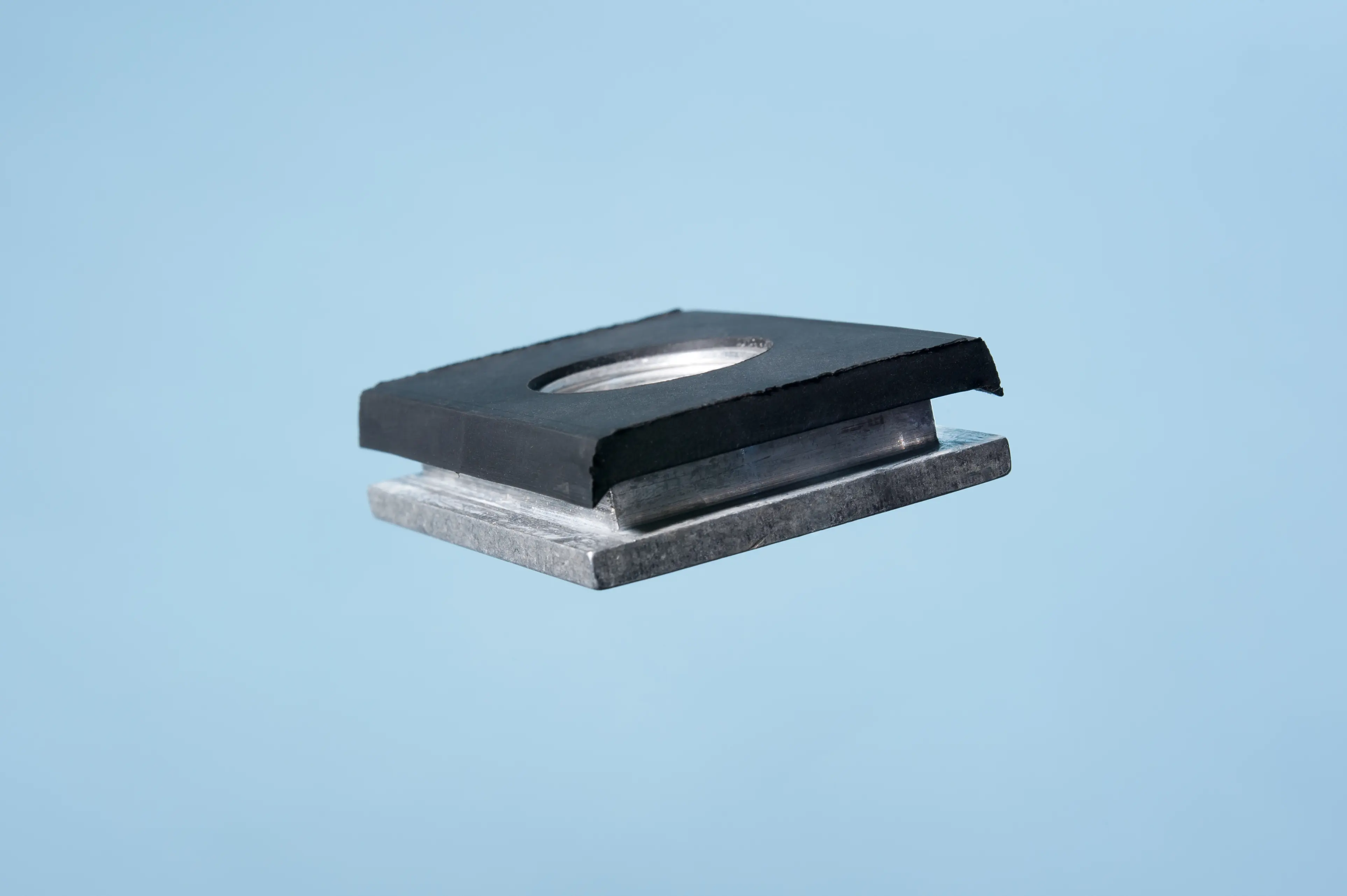

This innovative material, awarded and patented several times, cleverly replaces technical foams but can also provide you more.

This unique shape makes it possible to envisage endless applications in sectors such as construction, medical, sports and protective equipment.

Hexaflex …

3 main business sectors

CONSTRUCTION, ENERGY & SPORT

Head protection parts

We are specialised in thermoplastic injection moulding of hard hats and assembly of its components, in polyethylenes, polyamides or shock-resistant ABS. Our own Hexaflex solution is an innovative response to the protection needs of the body.

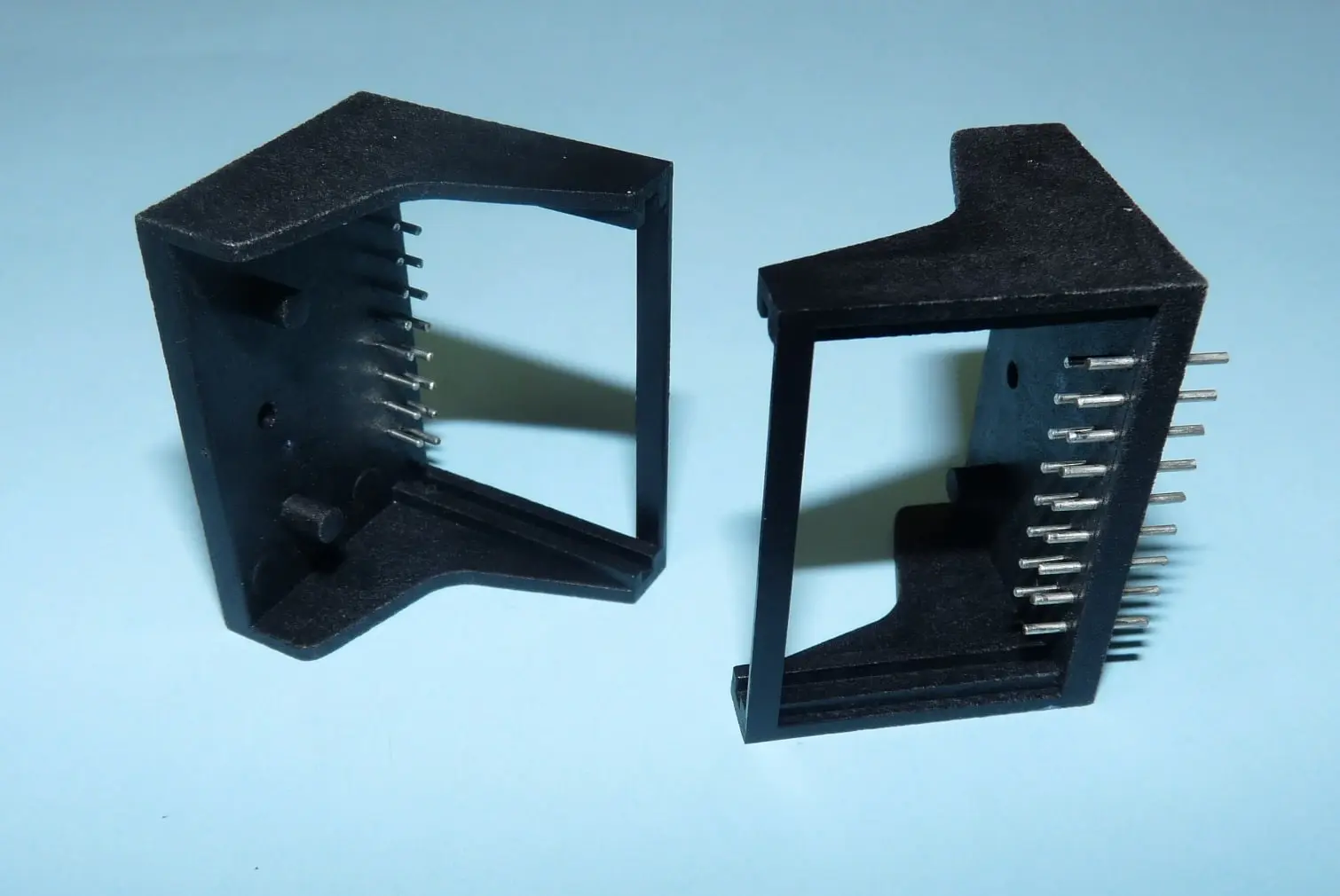

AERONAUTICS & DEFENCE

Connector parts

We develop high performance plastic parts for the aeronautics, defense and rail sectors.

EQUIPMENT INDUSTRY

Precision and functional parts

We manufacture small and medium-sized series of injected or moulded/overmoulded parts for various technical industries.

Our added value

Relying on recognised expertise and know-how, Delta Plasturgy supports its clients throughout all steps of their projects to offer the best response : Defining the shapes of a part, a feasibility study and creating moulds, selecting plastic material, manufacturing parts, finishing and assembly operations.

EXPERTISE IN MOULDING AND RAW MATERIALS

A SKILLED DESIGN OFFICE

A unique contact

FLEXIBLE PRODUCTION ORGANIZATION

EXPERTISE IN MOULD DESIGN AND CREATION

A COMPREHENSIVE MACHINE FLEET

Completed projects

Our news

Our participation in the BtoB event organized by NAE

On Wednesday April 10, the DELTA PLASTURGY JP team took part in the BtoB event organized by NAE (Normandie Aerospace) at the Zénith in Rouen. This day was...

Change of presidency DELTA PLASTURGY JP

Julien Fillot succeeds his father Jean-Jacques Fillot, and take over as president of DELTA PLASTURGY JP. He was in charge of managing the site alongside him...

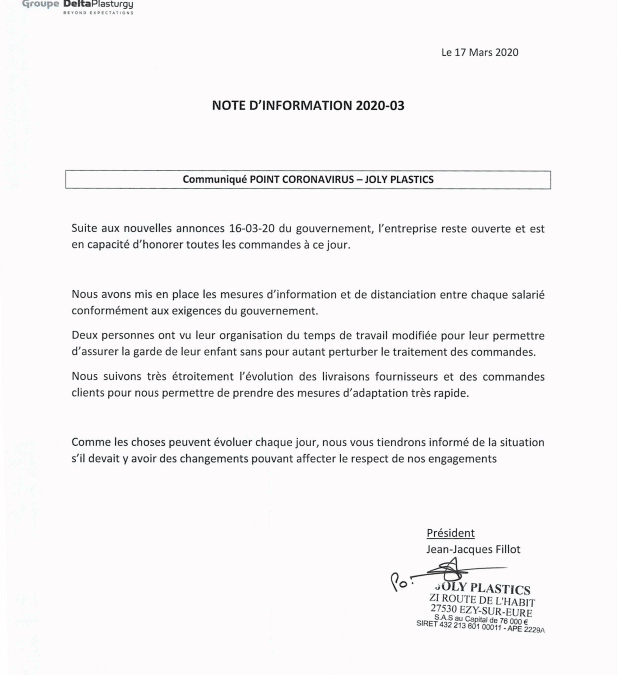

INFORMATION COVID-19

Above information about the current situation in our company from COVID-19

Our references